Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As the heavy equipment industry approaches 2025, several key trends are set to redefine the landscape, influencing innovations and operational efficiencies. Among these trends, the adoption of advanced technologies such as automation, artificial intelligence, and sustainable practices is gaining momentum. Companies like Sany Heavy Equipment, known for their commitment to innovation, are revolutionizing how heavy machinery is utilized in various sectors. This evolving environment presents both challenges and opportunities as businesses adapt to meet the demands of a changing market.

The integration of smart technologies in heavy equipment is not merely a trend but a necessity. With the growing emphasis on productivity and efficiency, manufacturers are increasingly investing in technologies that enhance machine capabilities, minimize downtime, and optimize performance. These advancements not only improve operational efficiency but also contribute to sustainability goals within the industry. As we look ahead to 2025, the influence of these trends will be significant, painting a picture of a more technologically sophisticated and environmentally conscious sector.

The landscape of heavy equipment is poised for transformative changes by 2025, driven by emerging technologies that promise to enhance efficiency, safety, and sustainability. One of the most notable trends is the increasing integration of artificial intelligence (AI) and machine learning. These technologies are set to revolutionize operations by enabling predictive maintenance, reducing downtime, and optimizing equipment performance. AI systems can analyze vast amounts of data from machinery usage and environmental conditions, allowing for smarter decision-making and preemptive repairs that minimize disruptions on job sites.

Additionally, the rise of automation and robotics is expected to redefine labor dynamics in the heavy equipment sector. Automated machinery, equipped with advanced sensors and navigation systems, will provide operators with tools to improve precision and reduce human error. This shift not only enhances productivity but also significantly improves worker safety by reducing the exposure of personnel to hazardous conditions. Furthermore, as the industry embraces electric and hybrid technologies, we can anticipate a decrease in carbon emissions. Companies are investing in cleaner energy solutions, which will contribute to long-term sustainability goals while addressing environmental concerns associated with traditional heavy machinery.

| Trend | Description | Expected Impact | Key Technologies |

|---|---|---|---|

| Autonomous Machinery | Increased use of self-driving equipment to enhance productivity and reduce labor costs. | Higher efficiency and productivity; safety improvements on job sites. | Lidar, GPS, AI-driven software |

| Electric Heavy Equipment | The shift towards electric-powered machines to reduce emissions and fuel costs. | Lower operational costs and environmental benefits. | Lithium-ion batteries, electric drive systems |

| Telematics | The integration of IoT for real-time data collection and machine monitoring. | Improved maintenance, reduced downtime, and enhanced fleet management. | IoT devices, data analytics platforms |

| Augmented Reality (AR) | Utilization of AR for training and maintenance processes. | Faster learning curves and improved maintenance accuracy. | AR glasses, simulation software |

| Sustainable Materials | Adoption of eco-friendly materials in manufacturing heavy equipment. | Reduced environmental footprint of construction projects. | Recycled metals, bio-composite materials |

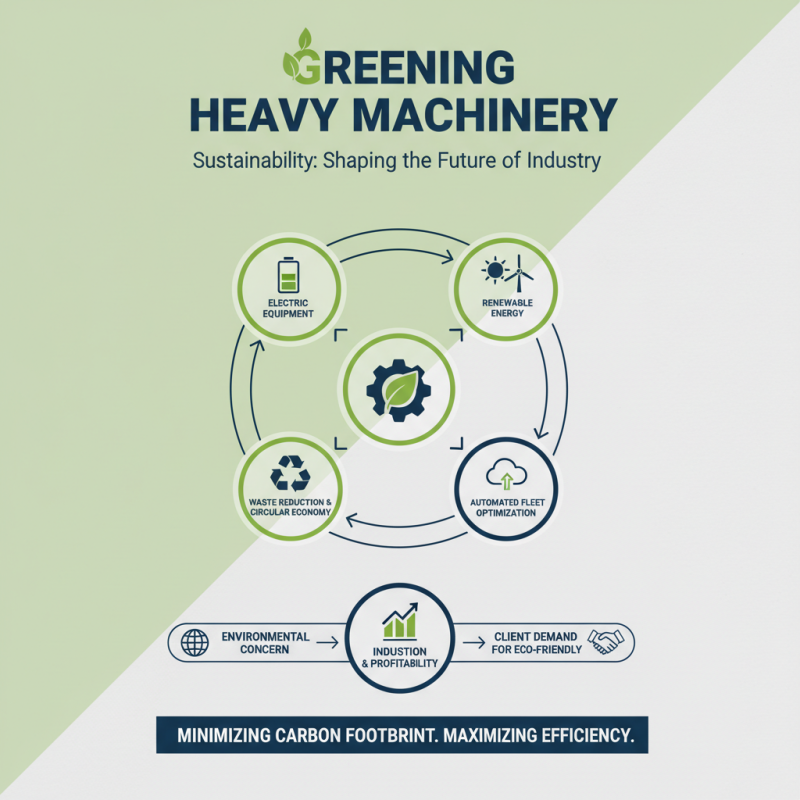

As the heavy machinery industry evolves, sustainability practices are becoming a crucial focal point that shapes its future. Companies are increasingly investing in environmentally friendly technologies and methodologies that minimize waste and reduce the carbon footprint. This shift not only addresses growing environmental concerns but also aligns with the demands of clients who prioritize sustainability in their operations. Innovative solutions such as electric equipment, renewable energy sources, and automated fleet management systems are making their mark, demonstrating the industry's commitment to greener practices.

Tips for integrating sustainability into heavy machinery operations include conducting regular energy audits to identify consumption patterns and areas for improvement. Another effective approach is to implement a comprehensive maintenance schedule that ensures equipment operates efficiently, thus extending its lifespan and reducing unnecessary waste. Additionally, considering a transition to alternative fuels or hybrid machines can drastically lower emissions while maintaining productivity and performance levels.

By embracing these sustainability practices, the heavy machinery industry not only prepares for the future but also sets a precedent for responsible corporate behavior. Companies that prioritize these initiatives are likely to gain significant advantages in a market that increasingly values environmental stewardship and corporate responsibility.

The heavy equipment industry is on the brink of a significant transformation, driven largely by advancements in automation and artificial intelligence (AI). By 2025, it is projected that 45% of heavy machinery will incorporate autonomous technology, enhancing operational efficiency and safety. According to a recent industry report, companies implementing AI-driven systems can boost productivity by up to 30%, allowing for better resource allocation and increased uptime. This shift towards automation not only addresses labor shortages but also mitigates the risk of human error, creating a safer work environment.

As heavy equipment operations integrate more AI solutions, it's crucial for industry players to stay ahead of the curve. Training programs focused on AI and machine learning are essential for upskilling the workforce. Operators should familiarize themselves with emerging technologies to maximize the potential of automated equipment. Moreover, investing in AI analytics can provide real-time insights, enabling quicker decision-making and predictive maintenance, ultimately reducing operational costs.

Tips:

1. Embrace continuous learning: Encourage team members to engage in training focused on automation and AI technologies.

2. Utilize data analytics: Leverage AI-driven analytics to enhance equipment performance and predict maintenance needs proactively.

3. Start small: Implement automation in phases, beginning with less complex tasks to allow for gradual adaptation to new technology.

The heavy equipment industry is poised for significant advancements in equipment design, driven by the dual imperatives of enhanced safety and efficiency. According to a report by the Association of Equipment Manufacturers, investments in safety technologies are expected to rise by 25% by 2025, reflecting the industry's commitment to reducing workplace incidents. Innovations such as advanced telematics are empowering operators with real-time data on equipment performance and safety metrics, allowing for proactive maintenance and improved operational safety.

One of the key trends in equipment design is the integration of smart technologies to streamline operations and minimize human error. Research from the International Society of Automation indicates that the implementation of automated systems can enhance operational efficiency by up to 30%. This is achieved through sophisticated algorithms that optimize equipment usage and reduce downtime. Furthermore, enhanced ergonomic designs are being prioritized to improve operator comfort and reduce fatigue, which is essential for maintaining high productivity levels. As the industry continues to embrace these cutting-edge trends, we can expect a safer, more efficient future for heavy equipment operations.

As we approach 2025, the heavy equipment industry is poised for significant growth, influenced by a range of market dynamics and economic factors. An increasing demand for infrastructure development and a focus on sustainable construction practices are driving investments in advanced heavy machinery. According to a recent market analysis by Allied Market Research, the global heavy machinery market is expected to reach $1 trillion by 2025, growing at a compound annual growth rate (CAGR) of approximately 5.4%. This growth is largely propelled by government initiatives aimed at enhancing public infrastructure and the expansion of mining and construction sectors.

Economic trends also play a crucial role in shaping the heavy equipment landscape. Fluctuating commodity prices and supply chain disruptions are factors that could impact equipment demand and pricing. However, with a projected rise in urbanization rates and a growing emphasis on smart city developments, the market is likely to stabilize and expand. Research from Grand View Research highlights that the adoption of automation and IoT in construction machinery will further drive efficiency and productivity, making it essential for companies to invest in these technologies to remain competitive.

Tip: Companies should focus on integrating digital solutions and automation in their heavy equipment to optimize operations and meet evolving market demands. Additionally, staying updated on economic indicators and supply chain developments can help businesses make informed decisions in this dynamic environment.