Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving machinery line industry, innovation is key to survival and success. Experts like Dr. Emily Carter, a leading authority in machinery efficiency, state, “Innovations are not just enhancements; they are necessities for competitive performance.” This statement rings true as we delve into the 2026 Best Machinery Line Innovations.

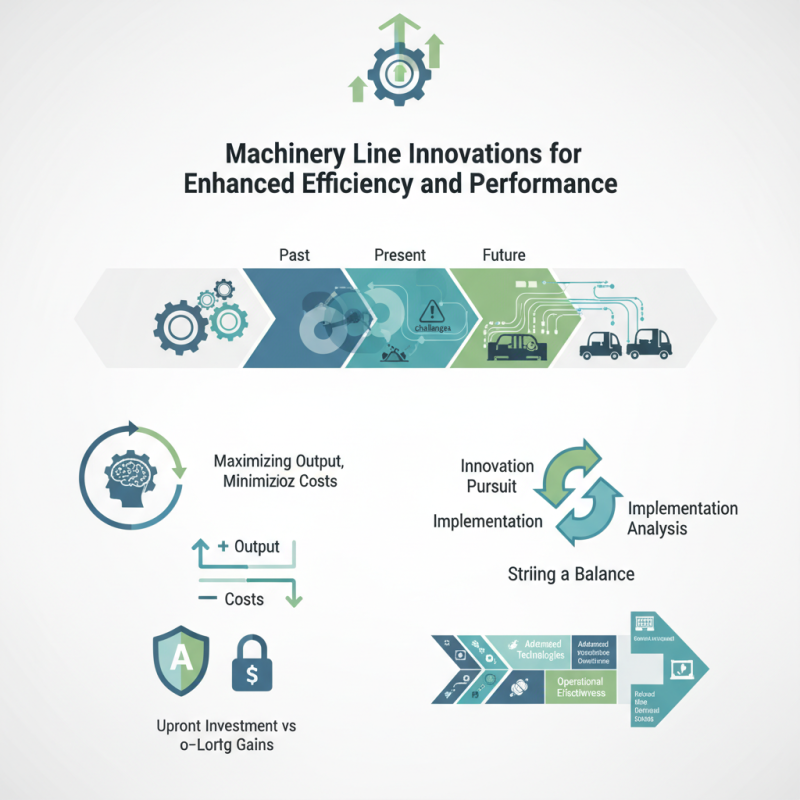

Today, companies face challenges in maximizing output while minimizing costs. Enhanced efficiency in machinery lines means integrating advanced technologies that improve performance and reduce downtime. For example, automated systems can streamline operations but may require significant upfront investment. As organizations innovate, they must evaluate their long-term gains against initial hurdles.

Reflections on past innovations reveal both successes and shortcomings. Many companies rushed to adopt the latest technologies, only to face integration issues later. Striking a balance between pursuit of innovation and thorough implementation analysis remains a challenge. The path forward in the machinery line sector demands not only cutting-edge advancements but also thoughtful consideration of their impact on overall operational effectiveness.

In 2026, advancements in robotics are transforming machinery operations. The integration of AI and machine learning leads to smarter machines. According to recent industry reports, robotic adoption in manufacturing is projected to increase by 20%. This could enhance productivity and reduce operational costs significantly.

Despite the benefits, challenges remain. Not all organizations are equipped to implement these technologies. Many workforce training programs lag behind technical advancement. This creates a skills gap, impacting efficiency. Companies must invest in employee education. Not every robot fits every task seamlessly. Custom solutions are often required, which can delay implementation.

Tips: Prioritize retraining your workforce. Evaluate how robotics can enhance existing processes. Regularly revisit your technological needs as the landscape changes. Stay adaptable. Embracing innovation without proper planning can lead to wasted resources.

The integration of AI technologies into machinery is revolutionizing efficiency. AI systems analyze data in real-time. They optimize operations by predicting machine wear. Predictive maintenance reduces downtime, which is crucial for productivity.

Operators benefit from AI-driven insights. They receive alerts for potential issues. This capability reduces human error and enhances decision-making. However, reliance on technology raises concerns. Are workers losing critical skills? As machines become smarter, the need for human intuition may decline.

Moreover, the learning curve for staff can be steep. Effective training programs are essential. Not every worker finds it easy to adapt. Some may struggle with AI interfaces and data interpretation. This disparity can lead to operational inconsistencies. Balancing advanced technology with human expertise remains a challenge. The key is finding harmony between man and machine in industrial settings.

Sustainable innovations in machinery design are reshaping the industry. Many companies are now focusing on reducing their carbon footprints. For example, using lightweight materials can decrease energy consumption. Innovations in automation also lead to more efficient processes. However, integrating these technologies often presents challenges.

Manufacturers are experimenting with renewable energy sources. Wind and solar power are becoming more common in factories. These changes can lower operating costs but may require significant upfront investments. Not every company can afford this transition. Additionally, training employees on new systems can take time and resources.

Designing for disassembly is another emerging trend. This concept allows for easier recycling of machinery parts. Yet, many designs still need improvement to achieve true sustainability. The industry must continuously evaluate these strategies. With each step forward, there is a need for reflection on their long-term impacts.

The chart above illustrates the percentage improvement in efficiency achieved through various machinery line innovations for 2026. Each category highlights the focus areas that contribute significantly to enhanced performance in machinery design and manufacturing processes.

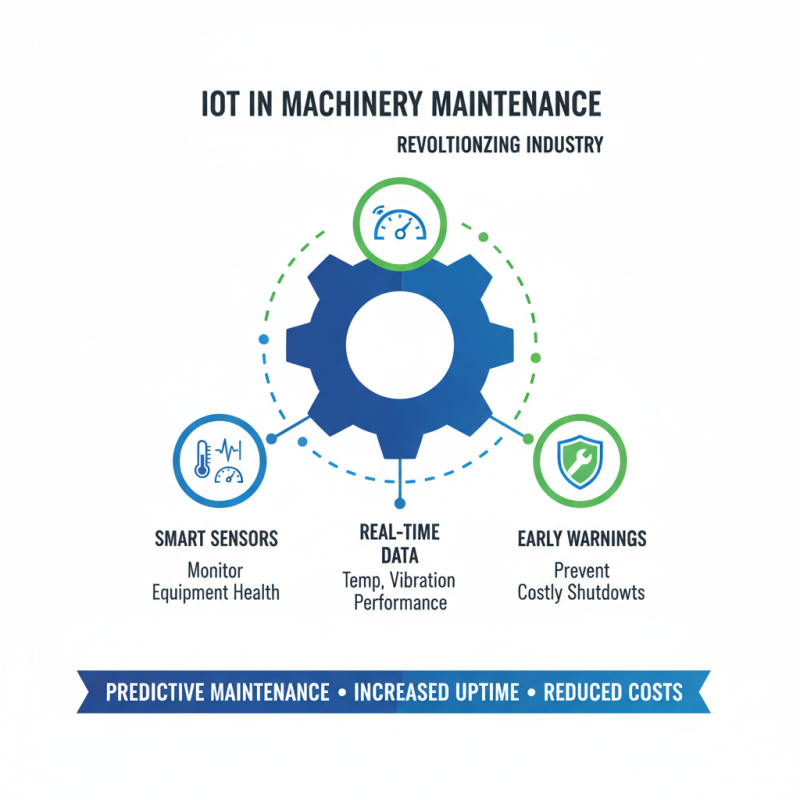

The integration of IoT in machinery maintenance is revolutionizing industries. Smart sensors monitor equipment health in real time. These devices track parameters like temperature, vibration, and performance metrics. This constant data flow helps identify potential issues before they escalate. Early warnings can prevent costly shutdowns and repairs.

However, implementing these systems is not without challenges. Many companies struggle with data overload. They need to filter useful insights from the noise. Training staff to interpret this information is crucial. Without proper understanding, simple mistakes can occur. Regular audits and recalibrations of the system must not be overlooked.

Investing in IoT solutions can significantly boost machinery efficiency. Yet, it requires a clear strategy. Not every organization is ready for this transition. A thoughtful approach ensures that the benefits of smart maintenance are fully realized.

In 2026, machinery lines are undergoing significant changes. Traditional machinery is often slower and less efficient. Innovative designs are now taking center stage. Some machines can adapt to different tasks with ease. These advancements save time and reduce costs, but are they always reliable?

Comparing traditional and innovative machinery reveals gaps in performance. Traditional machines may require fewer adjustments. They often have a proven track record. However, they lack the flexibility that new models offer. Innovative lines come with complex features that sometimes fail. It's essential to balance efficiency and reliability.

Many industries are experimenting with new machinery. Some have reported increased productivity. Yet, others have faced challenges in integration. New technology can be overwhelming. Workers may need additional training. This can lead to downtime and frustration. Striking a balance between traditional and innovative approaches is crucial for progress.

| Dimension | Traditional Machinery Lines | Innovative Machinery Lines |

|---|---|---|

| Efficiency (% increase) | 10% - 15% | 25% - 35% |

| Energy Consumption (kWh/ton) | 50 | 30 |

| Operational Cost ($/year) | $100,000 | $70,000 |

| Downtime (hours/year) | 200 | 80 |

| Product Yield (%) | 85% | 95% |

| Maintenance Frequency (times/year) | 12 | 4 |