Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the world of construction, selecting the right equipment is crucial. Crawler cranes play a pivotal role in various projects, from skyscrapers to bridges. Expert John Smith, a leading authority in crane technology, once stated, "The efficiency of a crawler crane can make or break a project." This highlights the importance of understanding these machines.

As we approach 2026, numerous crawler crane models are entering the market. Each offers unique features and capabilities. With advancements in technology, these cranes are becoming more versatile and user-friendly. However, not all models are suitable for every task. Companies must evaluate their specific needs when choosing a model.

The landscape of construction continues to evolve. While some models excel in lifting capacity, others may fall short in stability. This inconsistency can lead to costly mistakes. It is essential to analyze the strengths and weaknesses of each crawler crane model. A well-informed choice can enhance productivity and safety on site, helping avoid potential setbacks.

Crawler cranes play a vital role in construction projects. Their ability to move over rough terrain makes them suitable for various environments. These cranes are equipped with tracks, allowing them to navigate challenging job sites with ease. Operators often praise their stability and adaptability in different conditions. However, using crawler cranes is not without challenges.

For instance, setting up a crawler crane requires careful consideration of the ground conditions. If the soil is too soft, it may hinder the crane's performance. Additionally, the weight distribution can affect stability during operation. Operators must be vigilant about these factors. A minor oversight can lead to delays or accidents, emphasizing the need for thorough planning before deployment.

Moreover, maintenance is crucial for these cranes. Regular checks can prevent unexpected breakdowns. However, some teams may underestimate the time and effort needed for upkeep. This negligence could lead to operational inefficiencies. Despite their many advantages, crawler cranes demand respect and diligence from the operators to maximize their potential on construction sites.

When selecting a crawler crane for construction projects, key features are crucial. Load capacity stands out as one of the top considerations. Many projects demand cranes that can lift substantial weights. Reports show that cranes with a capacity of over 300 tons are in high demand. However, not all projects require such heavy lifting. Assessing the specific needs of your project is vital.

Mobility is another important factor. Crawler cranes need to navigate various terrains. A model that excels in rough terrain may not perform well on flat surfaces. According to industry research, around 45% of project delays result from equipment mobility issues. This raises the question: Is your chosen model fit for its environment?

Safety features can't be overlooked. Advanced safety systems are essential in cranes. They prevent accidents that could lead to substantial losses. However, some models still lack these modern upgrades. Data indicates that 60% of crane-related accidents are due to inadequate safety measures. When choosing a crane, always scrutinize its safety features. Prioritizing these elements can help ensure a smoother project execution.

This chart displays the maximum lifting capacities of various crawler crane models selected for construction projects in 2026. Each model demonstrates unique capabilities important for construction efficiency.

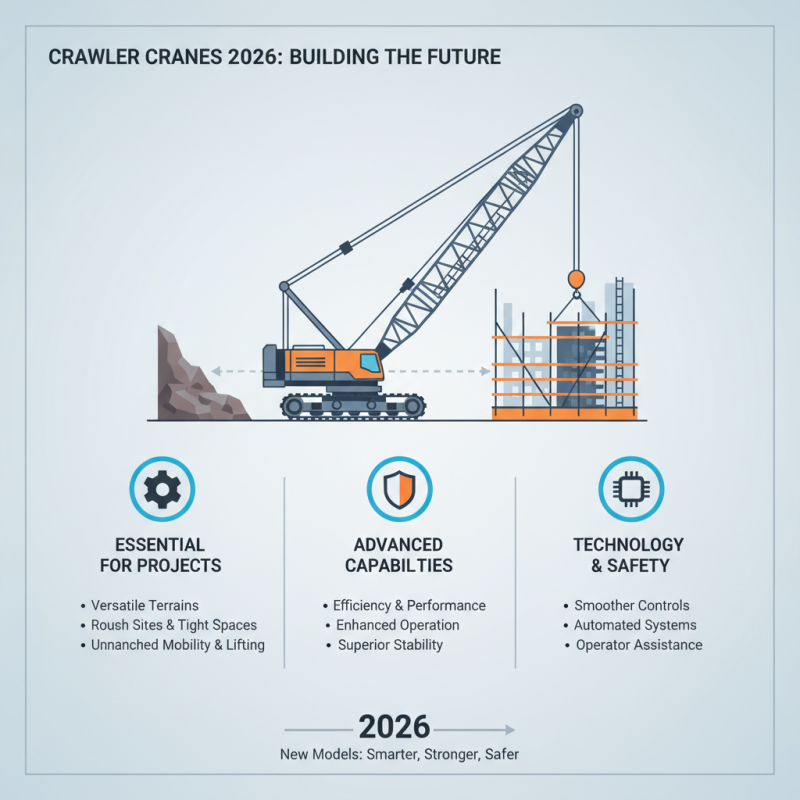

In 2026, crawler cranes are essential for construction projects. These machines excel in various terrains, from rough sites to tight spaces. Their mobility and lifting capabilities make them indispensable. The new models emphasize efficiency and performance. They incorporate advanced technology to enhance operation and safety. Operators can expect smoother controls and better stability.

Some models focus on fuel efficiency. This is important as costs rise and environmental concerns grow. However, not all models meet expectations. Some may struggle with load limits or terrain adaptability. These issues can lead to project delays or added expenses. An ideal crawler crane should balance power and agility.

When selecting a model, consider the specific project needs. Are you working on a large building or a bridge? The answer impacts your choice greatly. It's necessary to assess both performance and reliability. Not every machine is perfect, and sometimes even the best models require adjustments in the field. Reflecting on past experiences can guide future decisions.

When considering crawler cranes for construction projects, several brands stand out for their offerings. The cranes vary in size, lifting capacity, and advanced technology features. Many models range from 50 tons to over 600 tons in lifting capacity. According to industry reports, the global crawler crane market is expected to grow significantly, projected to reach approximately $5 billion by 2026.

It’s important to compare the capabilities of these cranes. Some models excel in rough terrains while others are designed for precision in urban environments. Operators often face challenges like limited maneuverability and harsh weather conditions. Understanding these limitations is essential when selecting a model for specific job sites.

**Tips:** Always assess the site conditions before choosing a crawler crane. Pay attention to the ground stability and load limits. This will impact safety and efficiency. Regular maintenance checks are a must, as neglect can lead to performance issues. Find out user experiences, as they often highlight practical challenges faced in real projects.

The crawler crane industry is evolving. Future trends focus on automation and sustainability. With advanced sensors, these cranes will enhance safety. They will automatically adjust to different site conditions. Improved stability will minimize accidents and errors.

Another trend is the use of electric power. This shift can reduce emissions significantly. The goal is to make construction greener. However, electric models face challenges in terms of power capacity. Battery technology needs improvement for long-term use.

Robotic integration is on the rise too. Remote operation can enhance efficiency. Yet, it introduces new complications with training operators. A balance between technology and human skill is vital. Adopting these technologies requires careful consideration. It’s essential to reflect on both benefits and possible drawbacks.

| Model | Max Lifting Capacity (tons) | Boom Length (meters) | Engine Power (HP) | Weight (tons) | Fuel Type |

|---|---|---|---|---|---|

| Model A | 120 | 60 | 450 | 40 | Diesel |

| Model B | 150 | 65 | 500 | 45 | Hybrid |

| Model C | 180 | 70 | 600 | 50 | Electric |

| Model D | 200 | 75 | 650 | 55 | Diesel |