Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right mini excavator for your construction project is crucial for maximizing efficiency and ensuring safety on site. With a multitude of options available in the market, making the right choice can seem daunting. Industry expert John Thompson, a seasoned construction equipment consultant, emphasizes, "Selecting the appropriate mini excavator can make the difference between a successful project and costly delays." His insights underline the significance of understanding both the specific requirements of your project and the capabilities of various mini excavator models.

Mini excavators are renowned for their versatility and ability to perform in tight spaces, making them a preferred choice in urban construction and landscaping projects. However, the selection process involves more than just size and power; factors such as operating weight, digging depth, and attachment options play a vital role in the machine's overall performance. By carefully assessing these parameters, project managers can ensure they choose a mini excavator that not only meets their immediate needs but also enhances productivity and cost-effectiveness in the long run. Understanding these elements will empower you to navigate the complexities of equipment selection and bolster the success of your construction endeavors.

When selecting a mini excavator for your construction project, it's essential to understand the various purposes and applications of these versatile machines. Mini excavators are primarily used for tasks in confined spaces where larger equipment cannot maneuver. They are perfect for landscaping projects, digging trenches, and performing site preparation work. Their compact size allows them to access areas that would otherwise be difficult to reach, making them invaluable for residential and commercial construction projects alike.

Tip: Before making a decision, evaluate the scope of your project and the specific tasks you need the excavator to perform. Consider factors such as the depth of excavation required, the type of soil you will be working with, and the terrain of the site. This assessment will help you identify the right specifications and attachments for your mini excavator.

Another important aspect to consider is the weight and size of the machine in relation to its lifting capacity. Mini excavators typically range from 1 to 10 tons, and the right choice will depend on the demands of your project. Ensure that the excavator you select can handle the load while also being light enough to avoid soil compaction that could damage your worksite.

Tip: Always read user reviews and seek recommendations from professionals who have experience with various models. Their insights will not only help you understand the practical applications of different excavators but also guide you toward a machine that is reliable and meets your specific needs.

| Feature | Description | Application |

|---|---|---|

| Weight | Typically ranges from 1 to 10 tons. | Used for small to medium scale excavation projects. |

| Digging Depth | Can reach depths of up to 12 feet. | Ideal for foundation digging and trenching. |

| Bucket Sizes | Usually available in sizes ranging from 12 to 36 inches. | Versatile use for various types of soil and material. |

| Hydraulic Power | Provides operation pressure ranging from 2500 to 3000 PSI. | Used for various attachments like grapples or breakers. |

| Operating Radius | Can vary widely, typically around 20 feet. | Useful in confined spaces and urban projects. |

| Fuel Type | Generally diesel, but some models offer electric options. | Consider for noise-restricted areas or environmental concerns. |

| Comfort Features | Often includes ergonomic controls and climate control options. | Enhances operator efficiency and reduces fatigue. |

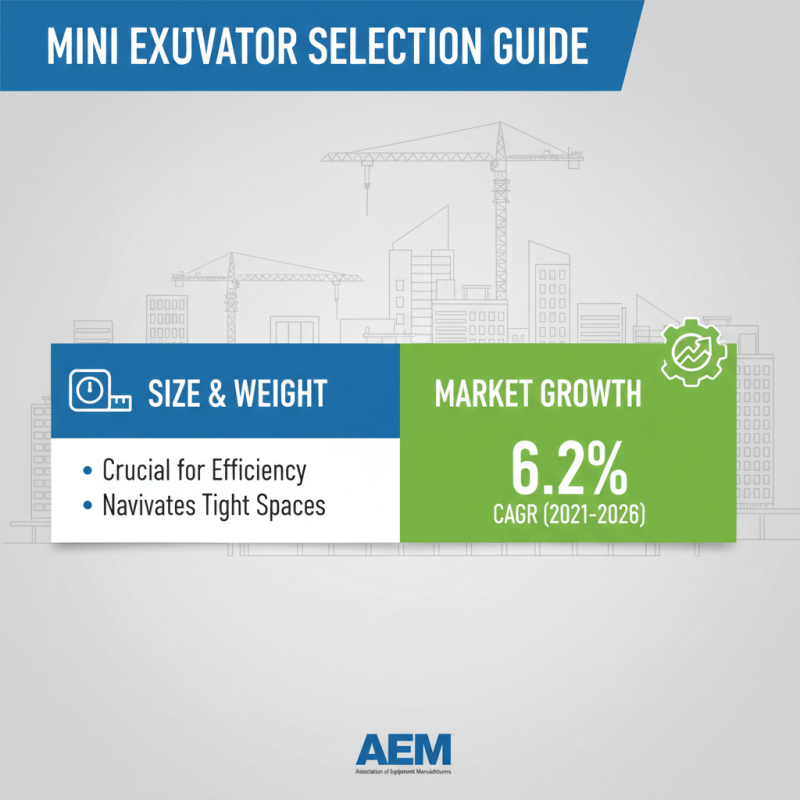

When selecting a mini excavator for your construction project, evaluating size and weight specifications is crucial to ensure efficiency and suitability for the job. According to a report by the Association of Equipment Manufacturers, the demand for mini excavators is projected to grow at a compound annual growth rate (CAGR) of 6.2% between 2021 and 2026. This growth reflects an increasing need for compact and versatile machinery that can navigate tight spaces often found in urban and suburban construction sites.

Understanding the weight class of a mini excavator can greatly affect its performance and mobility. Typically, mini excavators range from 1 to 8 tons. Machines in the 1-3 ton range are designed for light-duty tasks, such as landscaping and small excavation jobs, while those in the 4-8 ton range are more suited for heavy digging and site preparation. According to industry standards, a machine's weight directly influences its stability and digging power; however, heavier units may struggle in soft or uneven terrain. Hence, assessing the ground conditions and the job site's limitations will help determine the optimal size that balances maneuverability with necessary power.

Furthermore, the reach and digging depth are vital considerations linked to the excavator's size. Typically, smaller models can have a digging depth of up to 8 feet, whereas larger models can reach depths of over 13 feet. For instance, if a project involves deep trenching or foundation work, a machine with a greater digging reach and depth capability would be necessary. By carefully evaluating these specifications, contractors can select the most efficient mini excavator, optimizing both performance and cost-effectiveness for their specific project needs.

When choosing a mini excavator for your construction project, engine power and performance metrics are critical factors to consider. A mini excavator's engine power determines its ability to handle various tasks, from lifting heavy loads to digging deep trenches. It's essential to compare horsepower and torque ratings, as these metrics will influence the machine’s efficiency and effectiveness in your specific applications. Generally, higher horsepower equates to better performance, but it's also important to match the machine’s capabilities with the tasks you plan to undertake.

Tips: Look for a mini excavator that offers a balance between engine power and fuel efficiency. A machine that uses fuel wisely can save you significant costs over time. Additionally, evaluate the hydraulic systems in place; a more powerful hydraulic system will provide better digging depth and reach, allowing for a broader range of tasks to be performed with ease.

Moreover, consider the operating weight of the excavator. Heavier machines often provide better stability and traction, especially in rough terrain, but ensure that the site can accommodate their weight. Reviewing performance metrics such as cycle times and breakout force will give you insights into how quickly and efficiently the machine can handle tasks, which is crucial for keeping your project on schedule.

When selecting a mini excavator for your construction project, one crucial aspect to consider is the variety of attachments and features available. According to a report from the Association of Equipment Manufacturers (AEM), approximately 70% of contractors agree that the functionality of attachments significantly impacts project efficiency. Assessing your project's specific needs will guide you in choosing attachments that enhance your mini excavator's capabilities, such as buckets, hydraulic hammers, or grapples, which can all serve distinct purposes depending on the site environment.

Additionally, understanding the features of a mini excavator, like its operating weight, digging depth, and reach, will play a pivotal role in maximizing productivity. A study by the American Rental Association (ARA) indicated that mini excavators with advanced hydraulics and multifunction controls can increase operational efficiency by over 30%. This efficiency is not only vital for meeting project deadlines but also for minimizing labor costs.

Tips:

When budgeting for the purchase of a mini excavator, it’s crucial to consider not just the initial cost but also the long-term financial implications. The purchase price varies widely based on factors such as size, capabilities, and features. Before making a decision, carefully assess the specific requirements of your construction project. Additionally, exploring financing options can help manage the upfront expense while spreading payments over time, alleviating pressure on your budget.

Maintenance costs are another significant aspect of your budget. Regular servicing and upkeep are essential for the longevity and efficiency of your mini excavator, preventing breakdowns that could lead to costly repairs. Consider setting aside a percentage of the initial purchase price in a dedicated maintenance fund. This approach will ensure that you have the necessary resources for routine checks and any unforeseen issues that may arise, ultimately protecting your investment and ensuring smooth operation for your projects.