Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Mini Excavator can significantly impact the success of your project. According to a report by the Association of Equipment Manufacturers, the mini excavator market is projected to reach over $5 billion by 2025. These machines are versatile, ideal for small construction sites and landscaping projects. They offer efficiency and ease of use, making them a common choice for contractors.

However, many users often struggle with the selection process. Not every Mini Excavator suits every type of job. Some factors may lead to overspending or inefficient operations. For instance, understanding the machine's weight class and digging depth is crucial. Selecting a model that aligns with your specific project needs can prevent costly mistakes.

Besides size and capability, consider the attachment options. Many mini excavators offer various attachments for different tasks. Making the right choice can increase productivity. Ultimately, take the time to evaluate your project requirements carefully. A well-informed decision will yield better results and maximize your investment in this essential equipment.

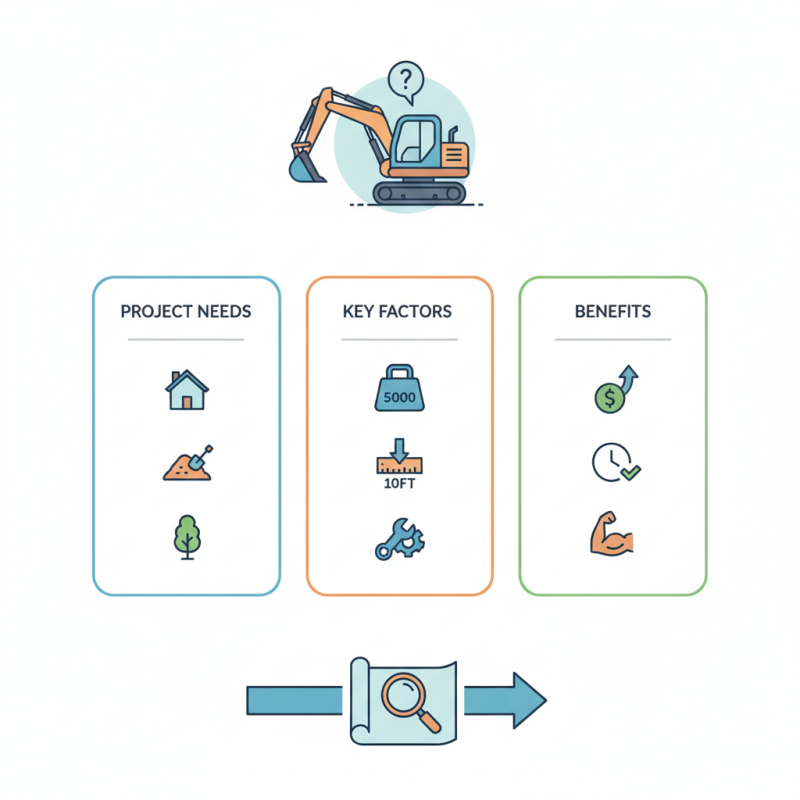

When selecting a mini excavator, understanding your project requirements is crucial. Assessing excavation depth and width directly affects the machine's suitability. For example, most projects require an excavation depth between 3 and 5 feet. However, some demand deeper digging, up to 10 feet. Many excavators can handle depths of a foot or two more than their specifications suggest, yet you should not assume this is always the case.

Width plays an equally significant role. A narrow width, often around 30 to 40 inches, allows for access in tight spaces. Yet, if the project involves larger areas, wider machines become necessary. According to industry reports, around 60% of job sites face space constraints. This statistic underscores the importance of measuring your work area accurately before choosing a machine.

Additionally, consider the soil type. Soft soils often require different attachments compared to hard rock. Data indicates that softer soil can increase excavation speed by up to 30%. However, underestimating required equipment can lead to delays and increased costs. Proper evaluation is key. Think about the impacts of these decisions. A mismatch can result in inefficiencies you could have avoided.

When selecting a mini excavator, weight class plays a crucial role. Mini excavators typically range from 1 to 10 tons, and this weight significantly affects performance. A 1- to 3-ton model is suitable for tight spaces, like residential projects. These machines are agile but may struggle with heavy materials. They are often preferred for landscaping and small-scale digging tasks.

On the other hand, the 5- to 10-ton class provides more power and stability. According to a recent industry report, excavators in this range can efficiently handle heavy lifting and complicated tasks. However, one must consider the terrain. Heavier models might damage delicate surfaces or compact soil, which is not ideal in all situations. Also, these larger machines require more space for maneuvering.

Ultimately, choosing the right weight class needs careful evaluation. If your project involves intricate work in confined areas, lighter models are better. But for larger excavation tasks, consider heavier options. Assessing the available space, project type, and load capacity can lead to a more informed decision. Always remember, what works best can differ widely based on specific job requirements.

| Weight Class (Tons) | Operating Weight (lbs) | Max Dig Depth (ft) | Max Reach (ft) | Bucket Capacity (cu. yds) |

|---|---|---|---|---|

| 1 Ton | 2,200 | 6.5 | 11.2 | 0.10 |

| 3 Tons | 6,600 | 8.5 | 15.5 | 0.15 |

| 5 Tons | 11,000 | 9.5 | 17.2 | 0.20 |

| 7 Tons | 15,400 | 10.5 | 18.8 | 0.25 |

| 10 Tons | 22,000 | 11.0 | 20.5 | 0.30 |

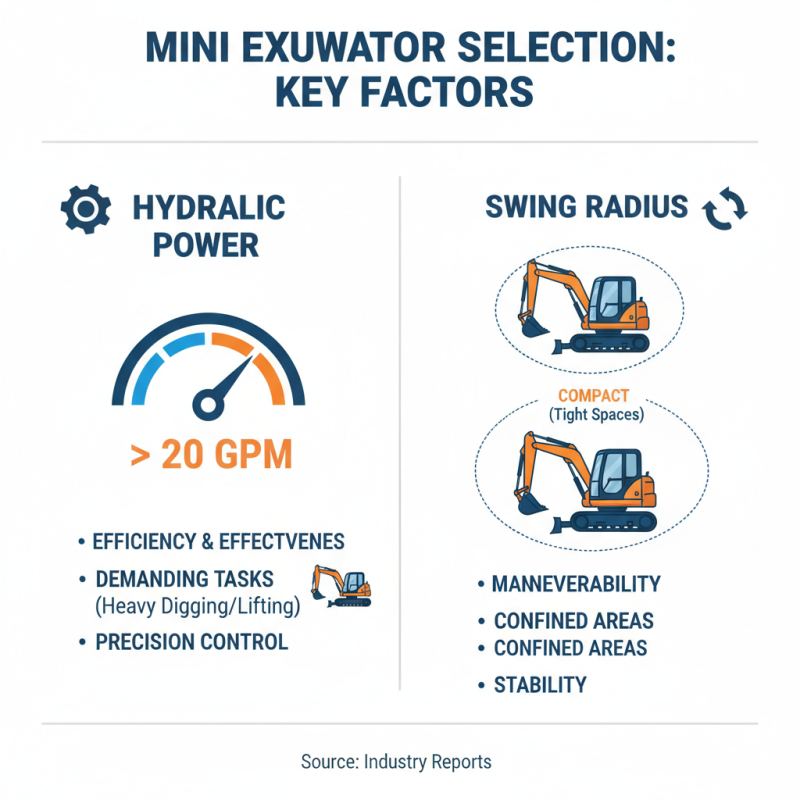

When selecting a mini excavator, hydraulic power and swing radius are crucial factors. Hydraulic power determines the machine's efficiency and effectiveness. According to industry reports, models with over 20 gallons per minute of hydraulic flow perform better for demanding tasks. This is essential for heavy digging or lifting operations. For projects requiring precision, a higher hydraulic flow translates to better control.

Swing radius, on the other hand, affects maneuverability in tight spaces. A compact radius enables the excavator to work in crowded job sites. Machines with a zero-tail swing design can operate near walls or obstacles without risk of damage. Studies show that models with a swing radius of less than 5 feet can significantly improve productivity in urban environments.

Tips: Always check the specifications before renting or buying. Evaluate your project’s space constraints and weight requirements. A machine that fits your project perfectly can save time and reduce costs. Consider the level of expertise required to operate the excavator effectively. Not every operator is familiar with high hydraulic power models. Understanding your team’s capability is key to choosing the right machine.

When considering a mini excavator for your project, the cost vs. benefit analysis is crucial. Rental might seem appealing. However, it's essential to evaluate if it meets your long-term needs. Industry reports indicate that renting can average $200 to $500 per day. For short-term projects, this could be beneficial. But for lengthy tasks, costs can add up quickly.

In contrast, purchasing a mini excavator can offer significant savings in the long run. The average price of a new unit ranges from $20,000 to $50,000. Over years of use, this investment can pay off. Yet, ownership brings responsibilities like maintenance and storage. Some may find it challenging to manage these ongoing costs. Data suggests that nearly 30% of owners struggle with unexpected repair expenses.

Assessing your project timelines becomes vital. If your needs are uncertain, renting provides flexibility. Conversely, consistent projects justify a purchase. Remember, the right choice hinges on your specific requirements. Reflect on how often you’ll use the machine. This reflection could save you money and stress in the future.

Choosing a mini excavator is not just about size or power. The brand and its service network play a critical role. A strong service support system can make or break your project. If your equipment breaks down, you need quick access to repairs. Otherwise, delays can cost you time and money.

When selecting a brand, look for companies known for their reliability. Check for local dealerships. They should provide easy access to parts and repair services. A brand with a robust service network can ensure that your mini excavator runs smoothly throughout your project. Maintenance becomes less stressful with the right support.

Seek recommendations from other operators. Personal experiences can shine a light on service quality. Consider brands with a history of long-lasting equipment. You might think all brands offer similar services, but that’s not true. Evaluate if they respond promptly to service requests. Not all brands prioritize customer support equally. Make sure you dig deeper.