Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

The Machinery Line industry is undergoing a profound transformation. Innovations are reshaping how we approach manufacturing and efficiency. According to Dr. Emily Martinez, a leading expert in Machinery Line technologies, “Embracing innovation is key to staying competitive in today’s market.” Her insights reflect a growing consensus in the industry.

Technological advancements are crucial. Automation, AI, and IoT are increasingly integrated into the Machinery Line. These tools streamline processes and boost productivity. However, not all implementations meet expectations. Companies must carefully assess their needs. Sometimes, the latest technology isn’t the right fit for every operation.

Sustainability is another pressing issue. Manufacturers face mounting pressure to reduce their environmental impact. Innovative machinery can lead to greener practices. Yet, this transition requires time and investment. The balance between innovation and practicality remains a challenge for many in the Machinery Line sector. Embracing change is important, but so is learning from mistakes.

The machinery industry is witnessing rapid transformations, particularly through automation and robotics. Automated systems are increasing efficiency in manufacturing plants. This shift reduces human error, but it raises questions about job security. Workers must adapt to new roles as machines take over repetitive tasks. Training is essential to bridge this gap.

Robotic advancements are also reshaping how tasks are performed. Collaborative robots, or cobots, work alongside humans, enhancing productivity. However, the integration of these technologies is not seamless. Technical glitches and implementation challenges often arise. Companies face pressure to maintain productivity while overcoming these hurdles.

Emerging technologies provide opportunities, but they come with risks. Investing in automation can lead to significant upfront costs. Companies must evaluate their return on investment carefully. As these innovations continue, finding the balance between technology and human touch remains a critical challenge.

The manufacturing industry is undergoing a significant transformation with a focus on sustainable practices. Eco-friendly innovations are becoming crucial. Companies are exploring ways to reduce waste and conserve resources. New materials are emerging that are easier to recycle. These changes not only benefit the environment but often lower production costs.

One way to begin this transition is through energy-efficient machinery. Switching to machines that consume less power can lead to substantial savings. Audit your current machinery for energy use. You might find opportunities for upgrades that align with sustainability goals.

Consider integrating renewable energy sources too. Solar panels or wind turbines can power manufacturing plants. This reduces dependence on fossil fuels. However, companies must reflect on the initial costs and feasibility. It’s essential to weigh short-term expenses against long-term benefits. Transitioning takes time and commitment, but the impact is profound.

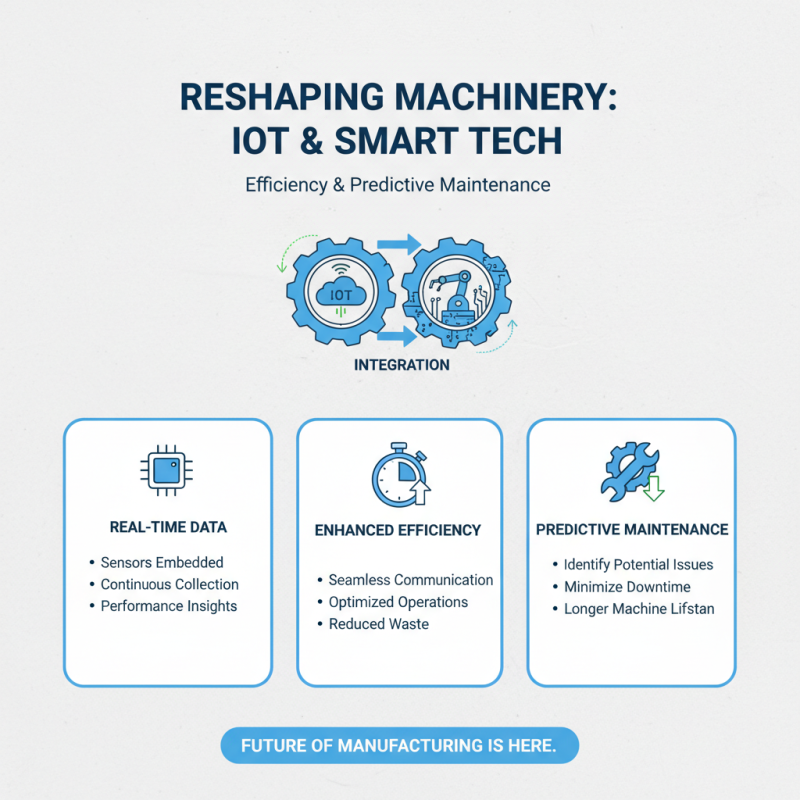

The integration of IoT and smart machinery is reshaping the machinery industry. These technologies enhance efficiency and foster real-time communication. Sensors embedded in machines collect data continuously. This data provides insights into performance and potential issues. It allows for predictive maintenance, reducing downtime.

However, the process is not without challenges. Many companies struggle with data overload. Sorting through vast amounts of information can be daunting. A clear strategy is essential. Focus on the most critical metrics for your operations. Not all data is valuable; prioritize wisely.

Tips: Implementing IoT requires a culture shift. Train your team to embrace new technologies. Conduct workshops to ease the transition. Regularly review the systems in place. Evaluate what works and what doesn’t. Adjust accordingly for continuous improvement.

The landscape of the machinery sector is changing rapidly. Additive manufacturing, especially 3D printing, is at the forefront of this transformation. According to a recent report by Wohlers Associates, the additive manufacturing market is projected to reach $35.6 billion by 2024. This shift highlights a growing reliance on technologies that can reduce production times and costs.

3D printing enables complex designs that traditional methods cannot achieve. For example, intricate geometries and lightweight structures are now possible, pushing the boundaries of engineering. However, there are caveats. Not all materials are suitable for 3D printing, limiting applications. Furthermore, quality assurance remains a major challenge. As production scales up, maintaining consistency in printed parts can become problematic.

Despite these hurdles, many firms explore innovative uses of this technology. It allows for rapid prototyping, which shortens product development cycles. Companies are also experimenting with localizing production, reducing lead times. Yet, the investment in 3D printing technology can be substantial. It requires careful consideration of ROI. Balancing innovation with financial viability is crucial in this evolving landscape.

| Innovation Trend | Description | Impact on Industry | Future Outlook |

|---|---|---|---|

| Additive Manufacturing | Utilization of 3D printing technology to create complex parts. | Increases efficiency and reduces waste in production processes. | Expected to reduce lead times and materials costs significantly. |

| Smart Machinery | Integration of IoT technologies in manufacturing equipment. | Enhanced monitoring and predictive maintenance capabilities. | Will lead to improved operational efficiency and reduced downtime. |

| Automation | Use of robotics to carry out repetitive manufacturing tasks. | Faster production rates and reduced human error. | Predicted to lead to greater labor efficiency and cost savings. |

| Sustainability Initiatives | Focus on reducing carbon footprints and using eco-friendly materials. | Positive impact on brand reputation and compliance with regulations. | Growing trend as consumers demand greener practices. |

| Augmented Reality (AR) | Application of AR for training and machinery operation. | Improves training efficiency and operator safety. | Increased adoption expected for training and maintenance applications. |

Data analytics is reshaping the machinery sector. It's driving productivity and efficiency to new heights. Recent studies show that companies leveraging data analytics can improve their operational efficiency by up to 30%. This change is critical in a competitive environment.

Analytics tools gather real-time data from machinery. They track performance, predict maintenance needs, and optimize operations. For example, predictive maintenance can reduce downtime by 25%. However, integrating these technologies is not always smooth. Companies face hurdles like data overload and systems compatibility.

Moreover, many organizations lack skilled personnel to interpret the data. This gap can hinder potential benefits. As the industry evolves, investment in training is vital. Companies must cultivate a workforce ready to harness analytics effectively. Embracing these innovations is essential, but the journey requires careful navigation.