Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Optimizing a Machinery Line is crucial for enhancing operational efficiency. Recent studies indicate that companies can improve productivity by up to 30% through effective machinery line optimization. This involves analyzing workflows, reducing downtime, and upgrading machine components. Industry experts highlight the significance of such enhancements.

John Smith, a renowned expert in process engineering, once stated, “The efficiency of your machinery line determines the success of your production.” This underscores the importance of continuous assessment and improvement. Many companies struggle with outdated processes and equipment. They often miss opportunities to streamline operations and reduce costs.

Moreover, adopting advanced technologies can further boost efficiency. For instance, integrating IoT devices allows real-time monitoring of machinery performance. However, organizations face challenges in implementing these solutions. Balancing costs with benefits requires thoughtful planning and analysis. Reflections on current practices can reveal gaps and areas for development.

Understanding machinery line efficiency metrics is crucial for optimizing productivity. Key metrics include Overall Equipment Effectiveness (OEE), cycle time, and yield. Industry reports indicate that companies with high OEE rates can boost productivity by up to 30%. Yet, many organizations struggle to measure these metrics accurately.

To enhance OEE, focus on reducing downtime. Identify bottlenecks in your line. Studies reveal that unplanned downtime can account for 15% to 40% of total production time. By implementing a robust maintenance schedule, businesses can decrease failures and improve operational flow. It’s essential to collect real-time data for analysis. Sometimes data can be misleading or incomplete. Reflect on how data collection systems can misrepresent actual performance.

Tips: Monitor cycle times closely. Any variation can indicate inefficiencies. Regular training for staff can significantly impact overall yield. Workers need to be aware of best practices and optimization strategies. Lastly, always reassess your metrics. Sometimes what worked last year may not hold today. The machinery landscape evolves quickly; stay adaptable.

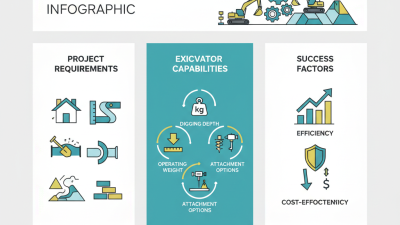

Identifying bottlenecks in production processes is crucial for optimizing machinery lines. Bottlenecks occur when a part of the process limits overall output. They can manifest due to slow machines, inadequate staffing, or inefficient layouts. Identifying these points requires careful analysis of workflows. Observations and data collection are key.

Talking to operators can reveal hidden issues. They often notice when machines fail to keep pace. This feedback can guide adjustments. For instance, if a machine requires frequent maintenance, it may slow down production. In these cases, investing in training or upgrading equipment might be necessary. Monitoring performance metrics regularly helps pinpoint recurring problems.

Sometimes, it's not just about machinery. Workflow can affect efficiency too. A poorly organized workspace can lead to distractions. Employees may spend too much time searching for tools. Redesigning the layout can eliminate travel time and increase productivity. Continuous reflection on these aspects can lead to better outcomes. Identifying and addressing bottlenecks promotes a smoother production process.

Predictive maintenance strategies are essential for optimizing machinery lines. These strategies leverage data analysis to anticipate machine failures. By monitoring equipment performance, businesses can schedule timely maintenance. This reduces downtime and enhances efficiency. However, implementing these strategies can be challenging. Organizations must ensure that they have the right tools and skills in place.

Data collection is critical in predictive maintenance. Sensors can track temperature, vibration, and other metrics. This data helps in making informed decisions. Yet, many companies struggle with data overload. Filtering relevant data can be complex but necessary. Without a clear plan, one might miss critical insights.

Training staff is another vital aspect. Employees should understand how to interpret data effectively. They need to feel comfortable using new tools. Change can be daunting; resistance is common. Addressing these issues upfront can lead to better outcomes. Investing in employee education fosters a culture of efficiency and adaptability.

Upgrading equipment is crucial for enhancing performance in any machinery line. Consider investing in newer technologies. These advancements can significantly reduce downtime. Outdated machines often face frequent breakdowns. This can lead to increased costs and lost productivity.

Implementing predictive maintenance schedules helps protect equipment integrity. It can prevent unexpected failures. Regular assessments of machinery can highlight issues before they escalate. Sometimes, this may reveal that certain machines need more than just minor upgrades. Perhaps a complete overhaul is necessary.

However, not every upgrade leads to success. Teams may struggle with new software or technology. Training staff is essential and often overlooked. It’s easy to assume everyone will adapt quickly. Realistically, some employees may resist change. It's vital to engage all team members in the process. This encourages ownership and collaboration, leading to genuine improvements.

In today's manufacturing landscape, leveraging automation and technology in machining lines is vital. Industry reports indicate that automation can improve production efficiency by up to 30%. This transformation allows for smoother operations and reduces human error. It’s essential to assess current machinery capabilities. Many companies find that outdated systems limit their productivity.

Integrating sensors and data analytics can reveal inefficiencies. For instance, predictive maintenance can reduce downtime by 25%. However, many businesses struggle with technical implementation. There's often resistance from employees worried about job security. Balancing technology integration with workforce education is critical. A seamless transition not only maximizes productivity but also maintains a motivated workforce.

Robotics are revolutionizing machining with precision and speed. Industry studies show that robotic solutions can handle tasks 50% faster than manual operations. However, this potential may not be fully realized without proper training. Investing time in upskilling employees ensures they can operate advanced machinery confidently. Embracing both technology and human expertise leads to greater adaptability in a rapidly evolving industry.